News

Launched a subscription service for "Invert Drilling & Placement Management Service".

Jointly developed "Invert Construction Monitoring System" using LiDAR with Toda Corporation

Launched a subscription service for "Invert Drilling & Placement Management Service".

~ Improved efficiency of a series of construction management from invert excavation to concrete placement at a low cost~.

(Head Office: Chuo-ku, Tokyo; President: Sadanori Iwamoto) and Toda Corporation (Head Office: Chuo-ku, Tokyo; President: Seisuke Otani) have jointly developed the "Invert*1 Construction Monitoring System," a LiDAR*1 based invert excavation and casting management system. The construction of this system will be completed by the end of March 2024, and the "Invert Excavation and Casting Management Service," a construction DX service for mountain tunnel construction work, will be launched as a subscription service on August 1.

LiDAR is attracting attention as a tool that can measure objects using reflected light emitted by laser beams and is less expensive than a 3D laser scanner. We developed a system that monitors the invert shape using LiDAR during invert excavation work to visualize the shape difference from the design data in real time, thereby contributing to work efficiency. The system also supports waste-free concrete ordering by predicting in real time the concrete capacity required during the pouring work.

1 LiDAR: A technology that emits laser light and measures the distance to an object and its shape based on the reflected light information. In recent years, LiDAR has been attracting attention as a relatively inexpensive tool for acquiring 3D point cloud information.

2 Invert: A portion of the tunnel bottom excavated in the shape of an inverted arch and hardened with concrete.

1. Background of development

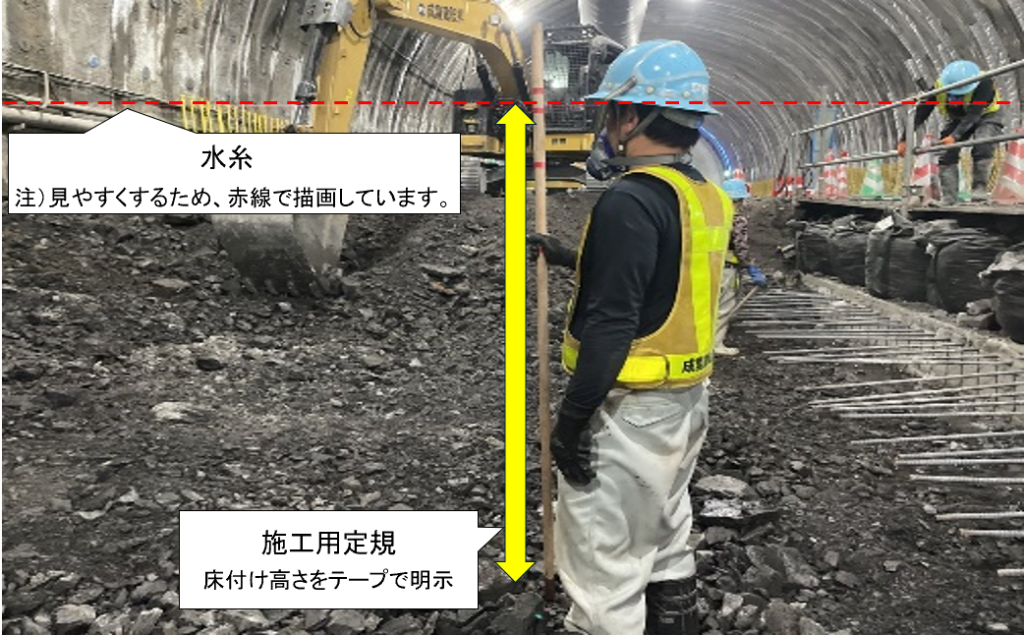

Conventionally, the state of finish of flooring excavation and the position of concrete finish for invert work were measured from a reference height set at the tunnel sidewall using water lines and a construction ruler (see Photo-1). The conventional method requires frequent human access to the work area of heavy excavation equipment for the purpose of form control, which may result in accidents due to contact with heavy equipment. In addition, the curved shape of inverts makes it difficult to accurately determine the required quantity of concrete, and there are concerns about the generation of leftover concrete due to over-ordering and the waiting time required for additional concrete in the event of under-ordering. In addition, concrete quality control requires proper control of the time from mixing to the end of placement, and in the case of placing two or more layers, the upper layer must be placed before the lower concrete layer hardens, so appropriate concrete placement control is required, such as indicating the concrete placement position according to the passage of time during concrete placement. Therefore, proper placement control is required, such as indicating the position of concrete placement according to the passage of time during concrete placement.

In order to streamline construction management operations that require a great deal of labor using conventional methods, we aimed to create an "easy-to-operate system" with simple and portable equipment that reduces installation costs and labor during operation.

Overview of the technology and its effects

The system consists of a LiDAR instrument for acquiring 3D information, a tripod, a portable battery, a Wi-Fi transmitter/receiver for data communication, and a tablet (iPad: equipped with iOS application for calculation processing and display) (see Photo-2). The acquired measurement data is communicated with the tablet in real-time, and the measurement results and the results (heat map) automatically calculated and processed by the application in the tablet are displayed on the tablet display.

The system consists of the following four modes for each construction phase.

Excavation status

Invert bedding excavation geometry (difference from design excavation line) is displayed on the tablet with a heat map (see Figure-1)

(Effectiveness) The tablet tablet enables the operator to check the excavation shape without omissions on a flat surface, thereby eliminating the need to excavate in excess or inadequate areas. In addition, the excavation cycle can be improved by reducing excess excavation, and the amount of concrete required for subsequent concrete placement can be reduced, which leads to productivity improvement by reducing the time and cost of concrete placement.

Excavation completed

Measure excavation surface at the completion of invert excavation and compare to design concrete finish location. Estimated amount of concrete required is calculated.

(Effectiveness) Concrete can be ordered in advance with high accuracy, and dispatch requests to and coordination with concrete plants can be efficiently carried out.

❸ Concrete pouring in progress

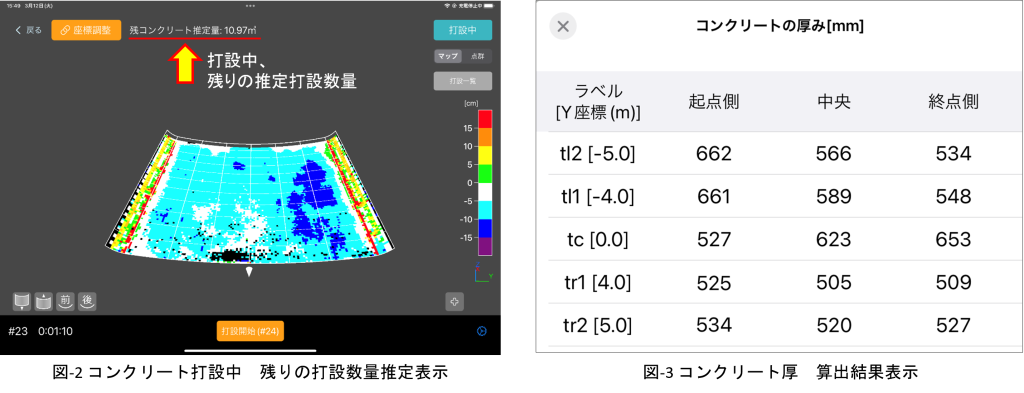

Real-time monitoring of changes over time during casting by measuring the shape of each transport vehicle after casting.

(Effect) - Since point cloud data with time information at the time of completion of concrete placement can be recorded, the elapsed time after unloading of concrete can be grasped, and the locations where the specified time has elapsed can be identified. This makes it possible to use the data to manage the time for placing concrete and to give appropriate instructions on the position of concrete placement.

The remaining quantity of concrete to be placed can be estimated in real time (see Figure-2), as can the estimated quantity of concrete to be placed at the completion of excavation. This allows for more accurate concrete ordering.

❹ Completion of concrete pouring

After the placement is completed, the concrete thickness is automatically calculated based on the difference between the shape of the concrete surface after placement and the shape of the bedding surface. The concrete thickness at any location is calculated and displayed, and a form of workmanship is automatically output (see Figure-3).

(Effectiveness) Automated output of workmanship forms streamlines the work of form generation.

3. Advantages of Introduction

- (1) Preparation and management work from equipment installation to completion of concrete placement can be performed by one person, and the processing time required from measurement to display of results is only about one minute, thus saving manpower.

- (2) Improved excavation cycle due to elimination of under-excavated areas and highly precise excavation with minimal excess excavation.

- (3) Improved work safety by eliminating the need for personnel to enter the work area for construction management

- (4) Concrete placing position can be indicated using point cloud data at the time of concrete placing with time information, which enables appropriate concrete placing control and improves concrete quality.

- (5) Expectations for cost reductions through reductions in excavation overburden and concrete use, as well as reductions in CO2 emissions and other environmental impacts

4. Future Prospects

In the future, we will proceed with full-scale operation of the system in the field and continue to improve the system to better suit site conditions in response to system operability and new problems that may arise. The system will be used to improve the productivity of invert construction management operations for mountain tunnels, as well as to improve the overall safety of invert work and the construction cycle, thereby solving problems at construction sites through DX promotion.

About GreenBee

Under the mission of “We are the company that utilizes digital technology to build a sustainable future”, GreenBee is working to create new value in three core businesses: the GX Service Business, which provides energy management services for a decarbonized society; the DX Service Business, which contributes to improved workflow; and the Technology Licensing Business, which licenses products based on our proprietary technologies.

https://www.greenbee.co.jp/

Contact information (for inquiries) (e.g. corporate phone number)

GreenBee, Inc. URL https://www.greenbee.co.jp/

Attn: TAKAHASHI e-mail:: press@greenbee.co.jp TEL: 03-6262-8660 FAX:03-5540-0211

8F., Central Square, 2-3-1 Shinkawa, Chuo-ku, Tokyo 104-0033, Japan